Cryogenic Dewar Cylinder

Product Description

The Cryogenic Dewar Cylinder is a stainless steel container with super vacuum insulation, designed for the storage, transportation, and use of liquid oxygen, liquid nitrogen, liquid argon, or carbon dioxide gas. These containers are manufactured in compliance with the DOT4L standard for reliable and economical transportation and storage of low-temperature liquefied gas, as well as for on-site storage and supply of low-temperature liquefied gas across a wide range of applications. Due to the strength and reliability of the Dewar Vessel, its long storage time, and its integrated gas supply system, the built-in regulator can continuously supply gas at normal temperature (oxygen, nitrogen, argon) at a flow rate of up to 9.2 m³/h. The outlet gas pressure reaches a constant level of 1.2 MPa (medium pressure type) / 2.2 MPa (high pressure type), fully meeting the requirements for normal gas conditions. If the user requires a large volume of gas, multiple Dewar Vessels can be connected in parallel, or an external regulator can be installed to meet the gas supply requirements. Installing an external regulator allows a single Dewar Vessel to achieve a gas flow rate of up to 30 m³/h.

Email: sales@jianshentank.com

Wechat/Whatsapp: +86 15517238365

Add: NO. 591 WENFENG ROAD, WENFENG DISTRICT, ANYANG, HENAN, CHINA

Product Description

The Cryogenic Dewar Cylinder is a stainless steel container with super vacuum insulation, designed for the storage, transportation, and use of liquid oxygen, liquid nitrogen, liquid argon, or carbon dioxide gas. These containers are manufactured in compliance with the DOT4L standard for reliable and economical transportation and storage of low-temperature liquefied gas, as well as for on-site storage and supply of low-temperature liquefied gas across a wide range of applications. Due to the strength and reliability of the Dewar Vessel, its long storage time, and its integrated gas supply system, the built-in regulator can continuously supply gas at normal temperature (oxygen, nitrogen, argon) at a flow rate of up to 9.2 m³/h. The outlet gas pressure reaches a constant level of 1.2 MPa (medium pressure type) / 2.2 MPa (high pressure type), fully meeting the requirements for normal gas conditions. If the user requires a large volume of gas, multiple Dewar Vessels can be connected in parallel, or an external regulator can be installed to meet the gas supply requirements. Installing an external regulator allows a single Dewar Vessel to achieve a gas flow rate of up to 30 m³/h.

Advantages of the Cryogenic Dewar Cylinder

Direct Gas Supply On-Site: Similar to using compressed gas cylinders.

Simple and Compact Piping: For centralized gas supply systems.

Use of Cryogenic Liquids: Enhances operational efficiency and reduces costs.

Key Benefits of the Dewar Cylinder:

Low Pressure Storage: Multi-layer protection, superior safety, and ease of reliable operation.

Large Storage Capacity: The capacity of a single DP175 gas cylinder is equivalent to nearly 30 standard gas cylinders (oxygen, nitrogen, argon).

Pure Container Body and Higher Gas Purity: As the gas is supplied directly from its liquid state, the risk of quality degradation due to secondary contamination during the filling, transportation, and usage stages of gas cylinders is eliminated.

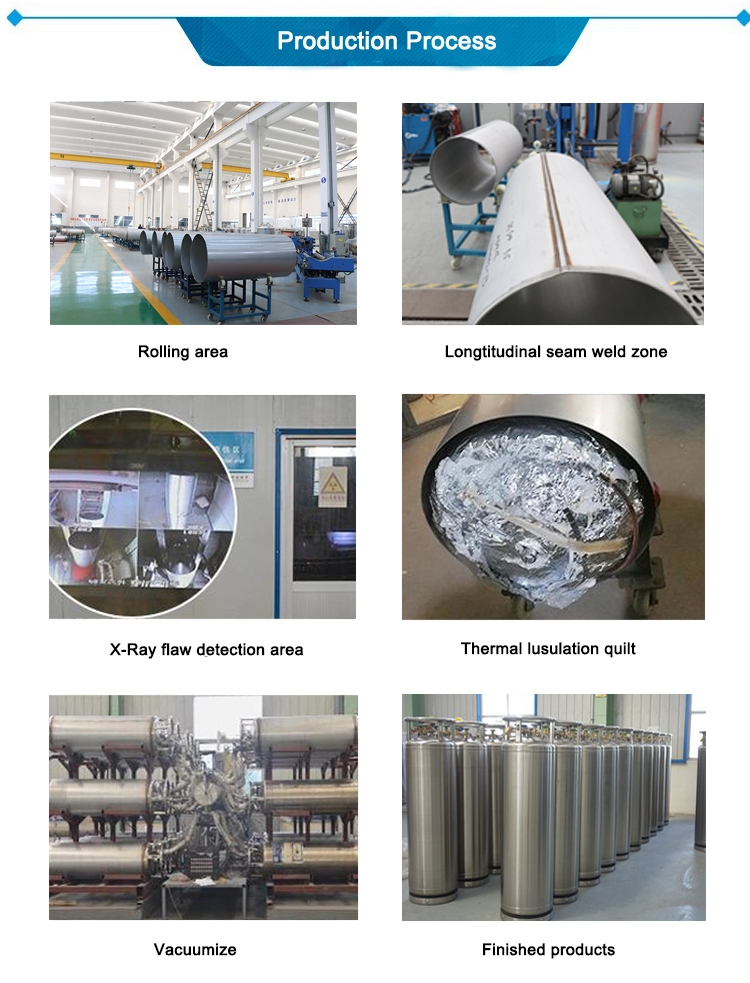

Product Process

The Cryogenic Dewar Vessel undergoes rigorous manufacturing and quality control processes to ensure it meets the highest industry standards. The vessels are designed with advanced insulation technology to maintain extremely low temperatures, ensuring the integrity and purity of the stored gases. The integration of a reliable gas supply system allows for continuous and efficient gas flow, making the Dewar Vessel an ideal solution for various industrial and scientific applications.

By leveraging the Cryogenic Dewar Cylinder, users can enhance their operational efficiency, reduce costs, and ensure the safety and purity of their gas supply.

Previous : Liquid Argon Storage Tanks: An In-Depth Overview

Next : Cryogenic LNG Storage Tank

Comments